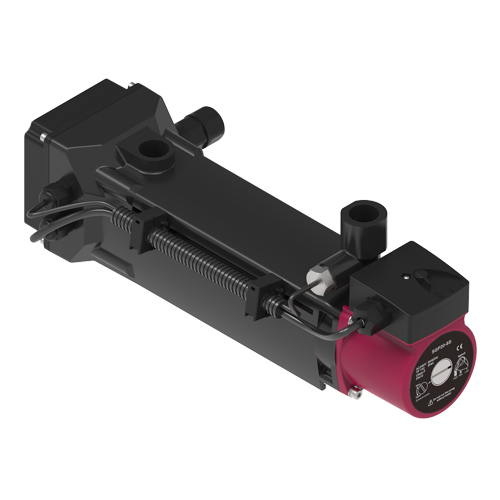

SmartGen HWP40N Engine Heater

Technical Parameters:

Rated Power 4000W

Rated Current 16.7A

Engine Displacement(L) 20?30

Thermostat Range Off: (5~70)?C On: (0~65)?C

Electrical Strength AC 1.5kV 1min

Insulating Resistance ?50M?

Inlet/Outlet Size G 3/4 Internal thread (Selectable Ô19.5mm Pagoda header or G 3/4 External thread)

Max. Water Pressure 0.5MPa

Protection Level IP44

Vibration Resistance (5~8)Hz Amplitude±7.5mm Triaxial (8~500)Hz a=2g Triaxial

Shock Resistance Half-sine Wave; apeak=50g; Triaxial

Case Dimensions(mm) 414*261*190

Weight(kg) 5.3(include accessories)

Product Overview:

HWP40N is a smart forced circulation heater of engine water. When engine operation temperature is below 4C, engine liquid coolant/lubricating oil may be coagulated to solid state in starting phase and lose lubrication or cooling effects, so that it may damage the engine. Therefore, heater shall be installed for engine to ensure normal starting and running.

It has lamp indication function, which can indicate all kinds of heater statuses. Heating temperature can be set by users, and dry burning prevention and overheating protection are fitted.

This product is suitable for various engines with (15~30)L displacement.

PERFORMANCE AND CHARACTERISTICS

- Micro-processor design is applied for the control part, precise temperature sampling, heating temperature can be set from control panel.

- 4-bit digital cube display is applied, which can show current coolant temperature, user defined temperature, accumulated running time, accumulated energy consumption, current voltage parameters etc.

- Water flow sensor is fitted, which can quickly detect shortage of water, pipe gas gathering, pipe clog, in order to prevent heater from dry burning, gas gathering etc. unhealthy phenomenon.

- Circulation pump and heater are controlled separately; water pump is firstly connected before heating, and then heater starts after delay for 5s; when it reaches pre-set temperature point, heater power is disconnected firstly; then water pump power is cut off after delay for 60s; this is to prevent heat gathering so that it can prolong pump life.

- Manual test function is fitted, which can check whether heating body and water pump is able to operate normally through panel button.

- Fine cast aluminum material is used for heater shell.

- Stainless steel inner heating pipes.

- Water drain valve is fitted at the bottom of the heating body, which can be used on demand.

- This product can work normally at -40? temperature.