SMARTGEN HGM1790N Manual/Remote Start Generator/Pump Controller Module

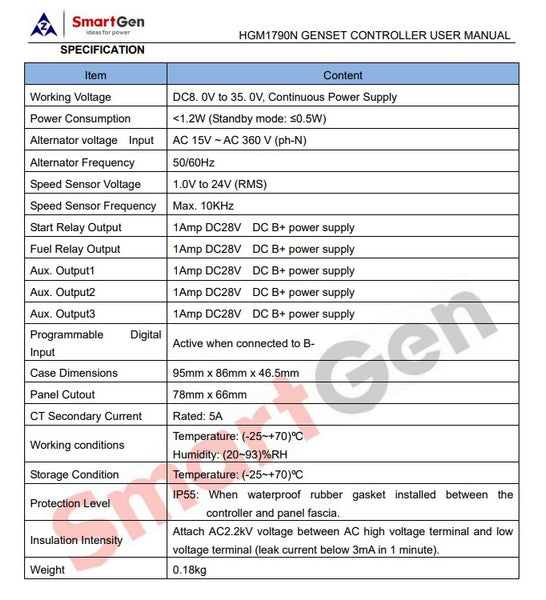

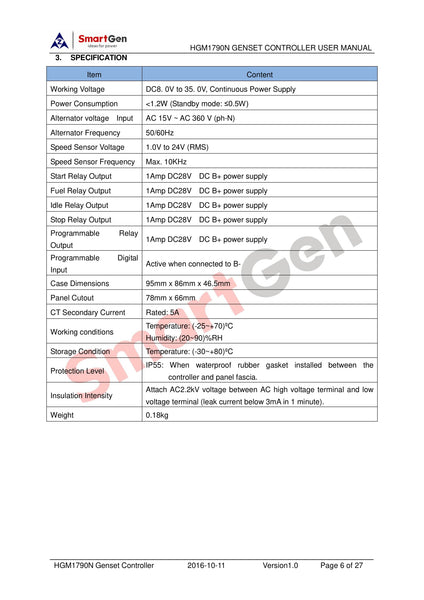

Technical Parameters:

Display LCD (with backlight)

Operation Panel Rubber

Language English

Digital Input 1

Relay Output 5

Analogue Input 1

AC System 1P2W

Alternator Voltage (15~360)V(ph-N)

Alternator Frequency 50/60Hz

kW/Amp Detecting & Display ●

Programmable Interface USB

DC Supply DC(8-35)V

Case Dimensions(mm) 95*86*46.5

Panel Cutout(mm) 78*66

Operating Temp. (-30~+80)℃

Product Overview:

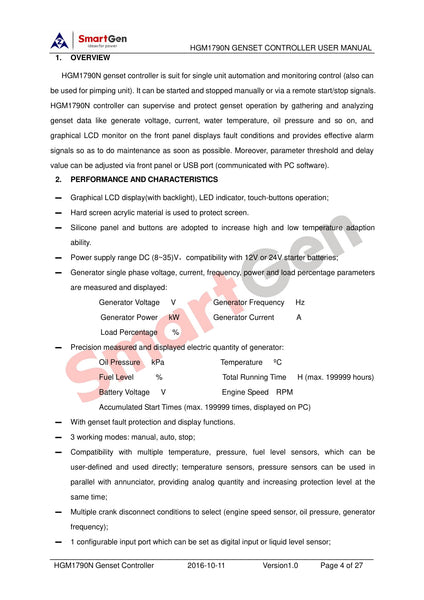

HGM1790N genset controller is suit for single unit automation and monitoring control (also can be used for pimping unit). It can be started and stopped manually or via a remote start/stop signals. HGM1790N controller can supervise and protect genset operation by gathering and analyzing genset data like generate voltage, current, water temperature, oil pressure and so on, and graphical LCD monitor on the front panel displays fault conditions and provides effective alarm signals so as to do maintenance as soon as possible. Moreover, parameter threshold and delay value can be adjusted via front panel or USB port (communicated with PC software).

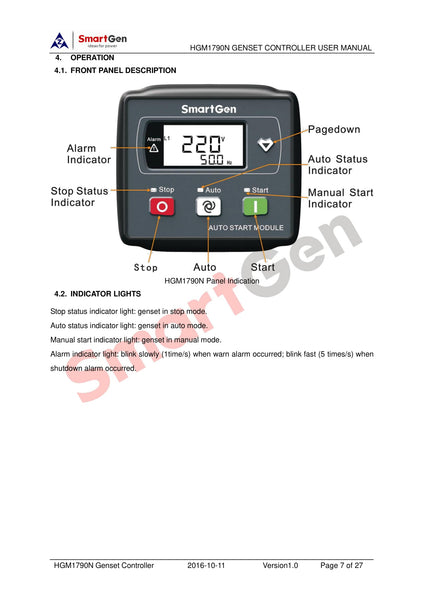

PERFORMANCE AND CHARACTERISTICS

- Graphical LCD display(with backlight), LED indicator, touch-buttons operation;

- Hard screen acrylic material is used to protect screen.

- Silicone panel and buttons are adopted to increase high and low temperature adaption ability.

- Power supply range DC (8~35)V, compatibility with 12V or 24V starter batteries;

- Generator single phase voltage, current, frequency, power and load percentage parameters are measured and displayed:

Generator Voltage V Generator Frequency Hz

Generator Power kW Generator Current A

Load Percentage %

- Precision measured and displayed electric quantity of generator:

Oil Pressure kPa Temperature ºC

Fuel Level % Total Running Time H (max. 199999 hours)

Battery Voltage V Engine Speed RPM

Accumulated Start Times (max. 199999 times, displayed on PC)

- With genset fault protection and display functions.

- 3 working modes: manual, auto, stop;

- Compatibility with multiple temperature, pressure, fuel level sensors, which can be user-defined and used directly; temperature sensors, pressure sensors can be used in parallel with annunciator, providing analog quantity and increasing protection level at the same time;

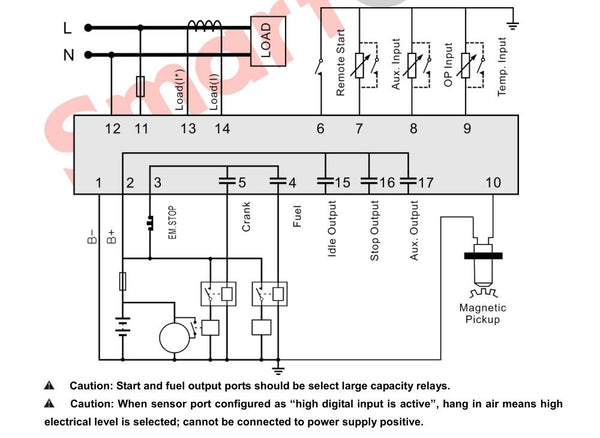

- Multiple crank disconnect conditions to select (engine speed sensor, oil pressure, generator frequency);

- 1 configurable input port which can be set as digital input or liquid level sensor;

- 4 fixed relay outputs (fuel relay, start relay, stop relay and idle relay);

- 1 configurable output port which can be set as common alarm output, fail to stop output, preheat output or idle control output;

- Parameters can be set and modified by users and saved in internal FLASH storage, which means that they will not be lost in case of power off. Most parameters of the controller can be modified using the front panel and all parameters can be adjusted by PC software via type-B USB port;

- Digital regulation of all parameters - instead of analog regulation using conventional potentiometer - and, therefore, higher reliability and stability;

- Modular design, self extinguishing ABS plastic enclosure and embedded installation way; small size and compact structure with easy mounting.