SmartGen HGM6120N AMF Genset Controller

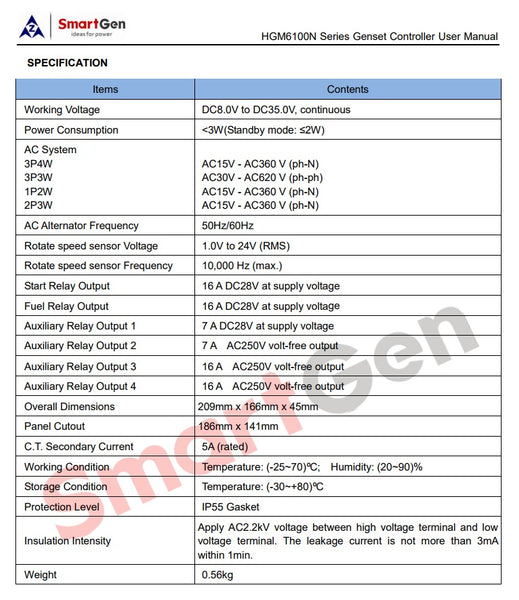

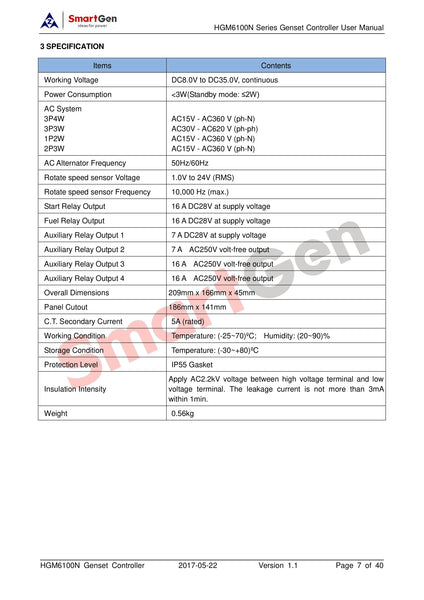

Technical Parameters:

Display LCD(132*64)

Operation Panel Silicon Rubber

Language Chinese & English & Others

Digital Input 5

Relay Output 6

Analogue Input 3

AMF ●

AC System 1P2W/2P3W/3P3W/3P4W

Alternator Frequency 50/60Hz

kW/Amp Detecting & Display ●

Programmable Interface USB

RTC & Event Log ●

Scheduled Start Genset ●

Maintenance ●

DC Supply DC(8~35)V

Case Dimensions(mm) 209*166*44

Panel Cutout(mm) 186*141

Operating Temp. (-25~+70)℃

Product Overview:

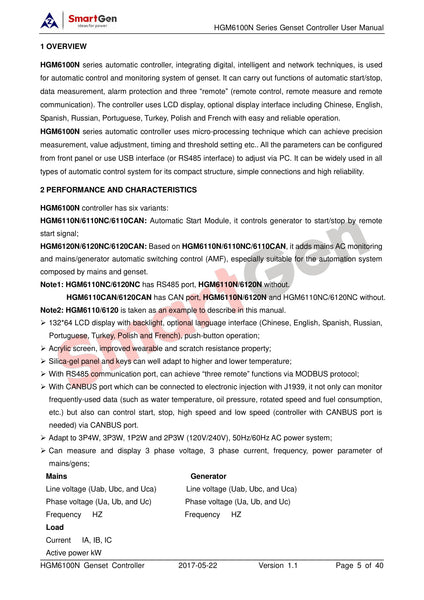

HGM6100N series automatic controller, integrating digital, intelligent and network techniques, is used for automatic control and monitoring system of genset. It can carry out functions of automatic start/stop, data measurement, alarm protection and three “remote” (remote control, remote measure and remote communication). The controller uses LCD display, optional display interface including Chinese, English, Spanish, Russian, Portuguese, Turkey, Polish and French with easy and reliable operation.

HGM6100N series automatic controller uses micro-processing technique which can achieve precision measurement, value adjustment, timing and threshold setting etc.. All the parameters can be configured from front panel or use USB interface (or RS485 interface) to adjust via PC. It can be widely used in all types of automatic control system for its compact structure, simple connections and high reliability.

PERFORMANCE AND CHARACTERISTICS:

HGM6100N controller has six variants:

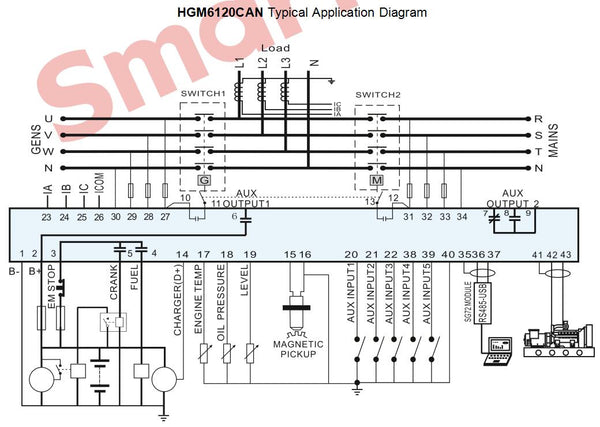

HGM6110N/6110NC/6110CAN: Automatic Start Module, it controls generator to start/stop by remote start signal;

HGM6120N/6120NC/6120CAN: Based on HGM6110N/6110NC/6110CAN, it adds mains AC monitoring and mains/generator automatic switching control (AMF), especially suitable for the automation system composed by mains and genset.

Note1: HGM6110NC/6120NC has RS485 port, HGM6110N/6120N without. HGM6110CAN/6120CAN has CAN port, HGM6110N/6120N and HGM6110NC/6120NC without.

Note2: HGM6110/6120 is taken as an example to describe in this manual.

1. 132*64 LCD display with backlight, optional language interface (Chinese, English, Spanish, Russian, Portuguese, Turkey, Polish and French), push-button operation;

2. Acrylic screen, improved wearable and scratch resistance property;

3. Silica-gel panel and keys can well adapt to higher and lower temperature;

4. With RS485 communication port, can achieve “three remote” functions via MODBUS protocol;

5. With CANBUS port which can be connected to electronic injection with J1939, it not only can monitor frequently-used data (such as water temperature, oil pressure, rotated speed and fuel consumption, etc.) but also can control start, stop, high speed and low speed (controller with CANBUS port is needed) via CANBUS port.

6. Adapt to 3P4W, 3P3W, 1P2W and 2P3W (120V/240V), 50Hz/60Hz AC power system;

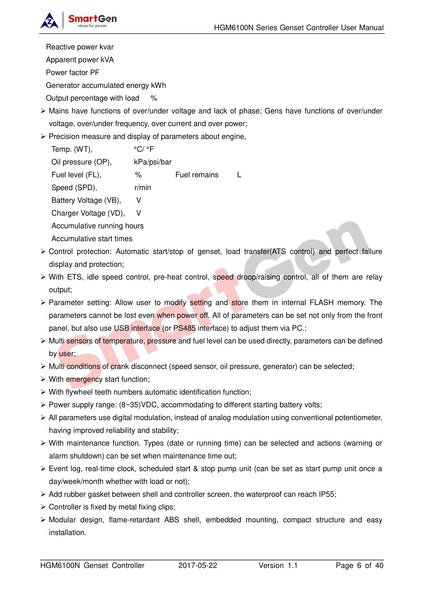

7. Can measure and display 3 phase voltage, 3 phase current, frequency, power parameter of mains/gens;

8. Mains have functions of over/under voltage and lack of phase; Gens have functions of over/under voltage, over/under frequency, over current and over power;

9. Precision measure and display of parameters about engine,

10. Control protection: Automatic start/stop of genset, load transfer(ATS control) and perfect failure display and protection;

11. With ETS, idle speed control, pre-heat control, speed droop/raising control, all of them are relay output;

12. Parameter setting: Allow user to modify setting and store them in internal FLASH memory. The parameters cannot be lost even when power off. All of parameters can be set not only from the front panel, but also use USB interface (or PS485 interface) to adjust them via PC.;

13. Multi sensors of temperature, pressure and fuel level can be used directly, parameters can be defined by user;

14. Multi conditions of crank disconnect (speed sensor, oil pressure, generator) can be selected;

15. With emergency start function;

16. With flywheel teeth numbers automatic identification function;

17. Power supply range: (8~35)VDC, accommodating to different starting battery volts;

18. All parameters use digital modulation, instead of analog modulation using conventional potentiometer, having improved reliability and stability;

19. With maintenance function. Types (date or running time) can be selected and actions (warning or alarm shutdown) can be set when maintenance time out;

20. Event log, real-time clock, scheduled start & stop pump unit (can be set as start pump unit once a day/week/month whether with load or not);

21. Add rubber gasket between shell and controller screen, the waterproof can reach IP55;

22. Controller is fixed by metal fixing clips;

23. Modular design, flame-retardant ABS shell, embedded mounting, compact structure and easy installation.